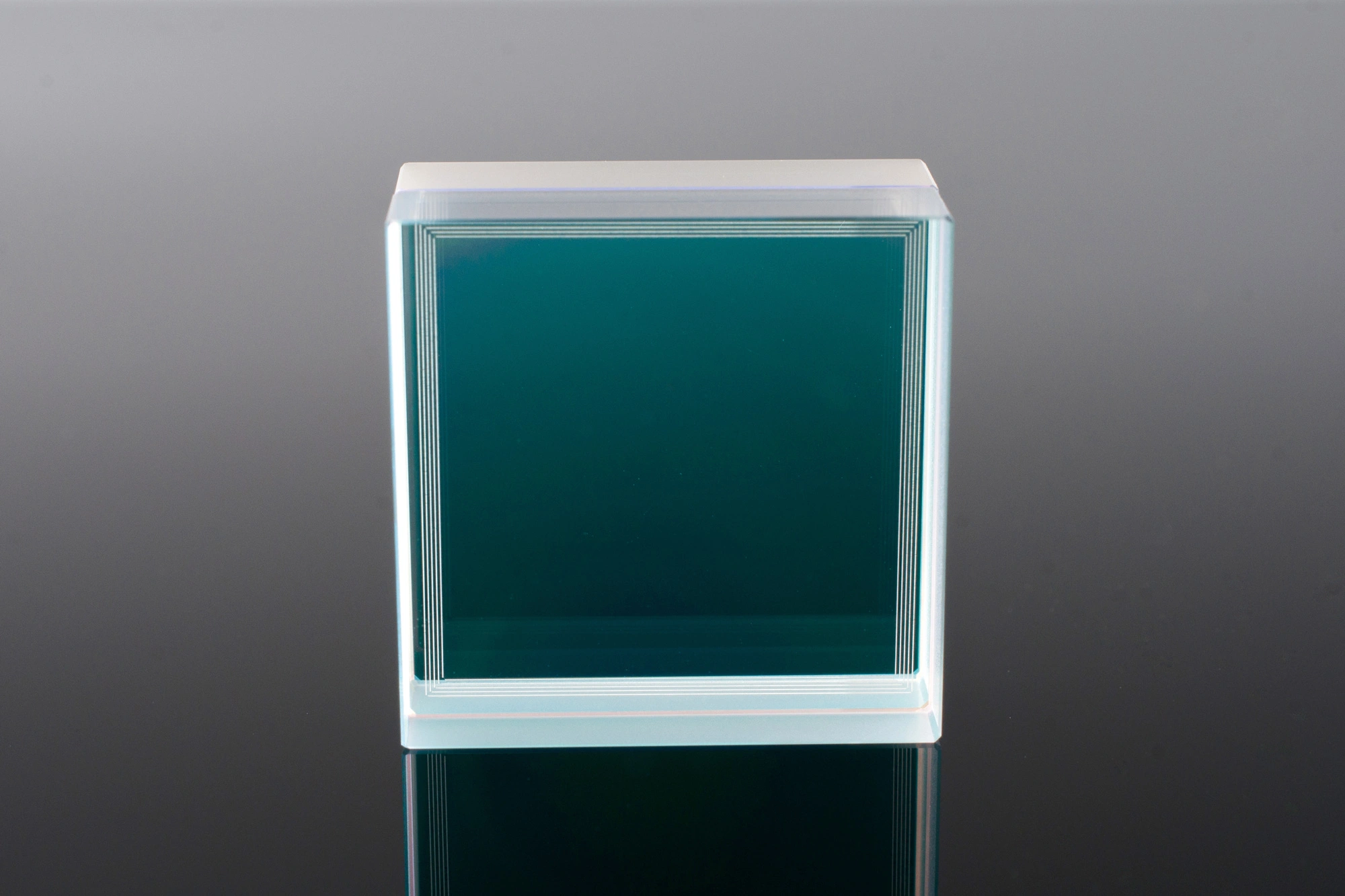

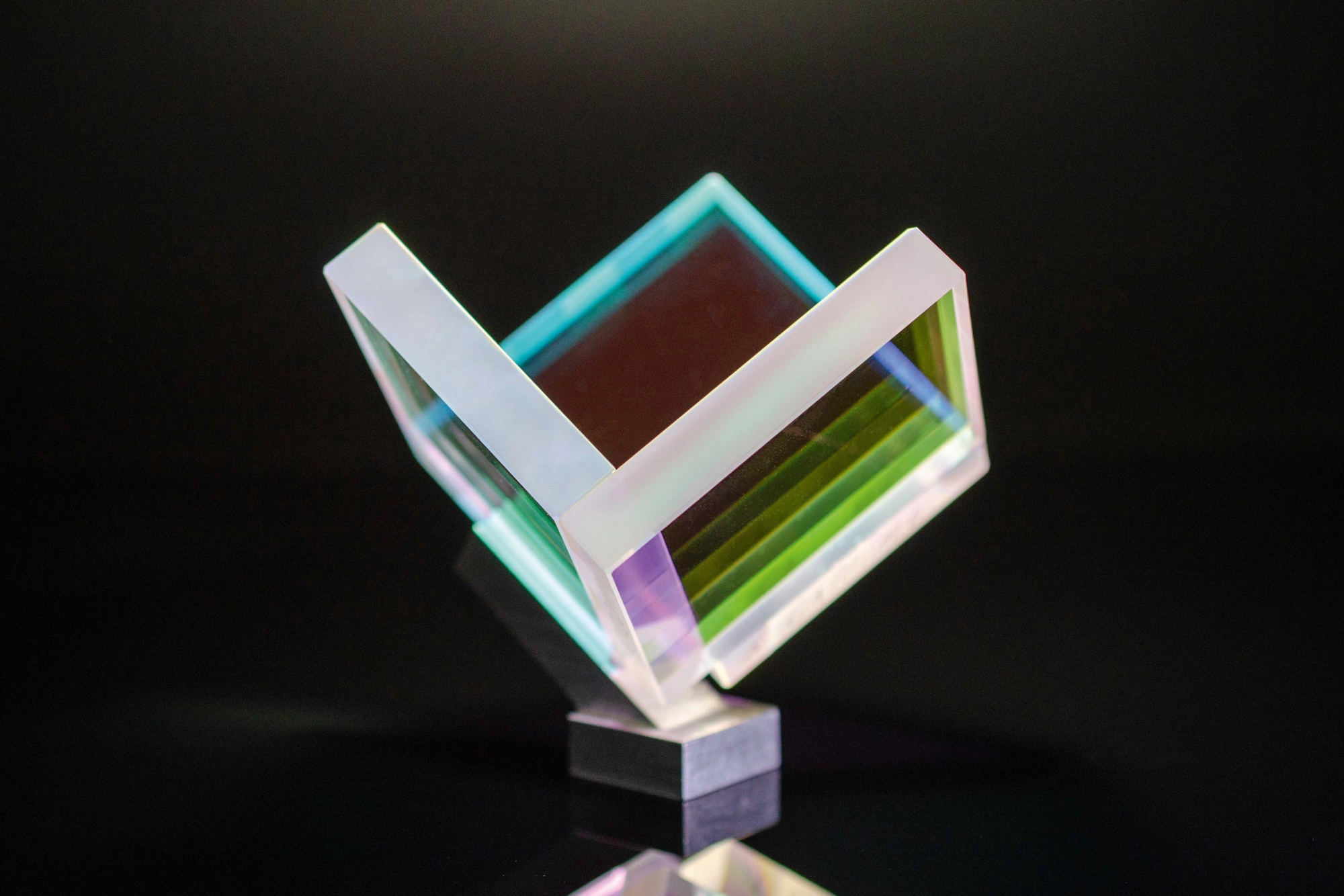

Optical Assemblies

Optical assemblies provide complex functionality and performance that might not be achievable with single components. The integration of multiple components into higher-level assemblies unlocks features and special properties, such as a broader spectral range of polarizing beam splitters or the combination of mechanical and optical functions.

LAYERTEC’s in-house capabilities include the handling, positioning, alignment, and mounting of optical and optomechanical components, as well as various joining techniques to meet challenging customer demands. These joining techniques range from cost-effective and flexible adhesive bonding to organic-free optical contacting and bonding techniques suitable for high power and UV applications. Our special bonding process and the ultrafast laser micro-welding process are best suited for high-precision assemblies with demanding alignment tolerances. Both processes provide very high mechanical strength and long-term stability even under challenging environmental conditions. Since both techniques result in intermediate layer-free bonds, they offer the lowest possible absorption and a high laser-induced damage threshold.

Building on long-lasting expertise, LAYERTEC can support the development and engineering of customer-specific solutions, from component and coating to the optical assembly. Our engineering support includes assistance with component design, material selection, determining substrate geometries, selecting appropriate fabrication techniques, and choosing suitable coatings, as well as the application of appropriate mounting and joining technologies according to your application requirements. Furthermore, LAYERTEC provides functional testing and optical metrology, as well as mechanical and environmental testing to ensure performance specifications.

All the optics shown represent just a few manufacturing possibilities that have already been successfully realized. LAYERTEC’s strength lies in finding individual solutions for complex problems.

Custom Optics / Optical Assemblies

- Retro-reflecting hollow roof mirrors / hollow retro-reflectors

- Effective zero-order waveplates

- Beam Splitters

- Optical Cavities

- Customized mounted and unmounted laser optic assemblies

Typical Specifications (others on request)

- Dimensions 0.5"…2"

- Clear aperture > 90 %

- Surface imperfection tolerance: 5/ 1 x 0.016 L1 x 0.004

- Surface form tolerance: λ/4

- Angular Accuracy: ≤5 arcsec (depending on geometry)

- Lateral Accuracy: ≤10 µm (depending on geometry)

Materials

- Fused Silica

- ULE®

- Crystalline Quartz

- Various optical glasses and crystals

- Metal mounts and holders

Most of LAYERTEC’s specialized coatings can be applied to individual components prior to joining or to the optical assembly after joining. Please contact us to select appropriate coatings to satisfy your needs.

Capabilities and Expertise

- Customized equipment for handling, adjustment, mounting, and joining

- Optical Alignment capabilities and adjustment techniques

- Support in engineering and production of prototypes to volume series

- CNC machining of opto-mechanical components

- Functional testing and optical metrology

- Mechanical and environmental testing

Joining Technologies

- Adhesive bonding

- Optical contacting of highly planar glass surfaces

- Bonding of surface-activated polished surfaces

- Ultrafast laser micro welding

Benefits

- High thermal, mechanical, and long-term stability

- Robust against thermal and environmental loads

- Organic-free bonds with ultra-low absorption

- High damage threshold, suitable for high power and UV use

- Suitable for vacuum use, fluidic/hermetical sealing

- Low wave front distortion

- High adjustment accuracy

Address

LAYERTEC GmbH

Ernst-Abbe-Weg 1

99441 Mellingen

Germany

International Sales

US Sales Office

Social Media

© 2024 | LAYERTEC GmbH