Ultrafast Mirrors

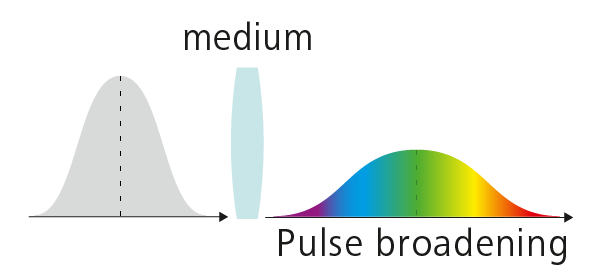

An ultrashort laser pulse contains a large number of synchronized individual waves of different wavelengths. When the pulsed laser beam passes through an optical system, the wavelength-dependent delay (dispersion) of the individual waves causes differences in propagation time. As a result, the laser pulse broadens and the pulse energy decreases. For laser systems of this kind, optics are required which cancel out these differences in propagation time (GDD).

LAYERTEC has been producing chirped mirrors for European research and development institutions and laser manufacturers, among others, since 1996. In several hundred scientific publications on the development of short pulse laser techniques LAYERTEC is mentioned as a supplier of customized components.

Chirped dielectric systems are sputtered at our company and thus achieve very good long-term stability in their optical properties. The following aspects have to be considered:

- Complex chirped coating systems should be applied to simple substrate geometries with functional areas as small as possible.

- We coat round optics with a diameter of 12.7 mm – 25 mm or rectangular optics with incident areas of 10 x 40 mm2 – 15 x 45 mm2 as standard.

- Customized substrate geometries are possible.

We have measuring stations to determine the dispersion of planar chirped optics in the wavelength range of 250 – 1700 nm.

Chirped Mirrors

When an ultrashort laser pulse passes through an optical system, its shape changes. Due to the wavelength-dependent dispersion, each individual wave is delayed to a different extent and differences in propagation time occur. As a result, the laser pulse broadens and the pulse energy decreases. To neutralize this effect, chirped mirrors are used.

LAYERTEC produces special dielectric systems (mirrors, pump mirrors, short-pass or long-pass filters, decouplers, etc.) with an adapted influence on the phase response (i.e. negative or positive GDD) in the wavelength range 200 – 5000 nm on customer request.

Phase correcting reflective systems with bandwidths, of a simple Bragg mirror (classical λ/4 mirror) or larger are called chirped mirrors. Phase-correcting mirrors for ps lasers with a (high) negative GDD over only a few nm bandwidth, on the other hand, are called GTI mirrors.

Chirped mirrors with a bandwidth on the size of a Bragg mirror can usually be calculated and fabricated without more oscillation of the GDD.

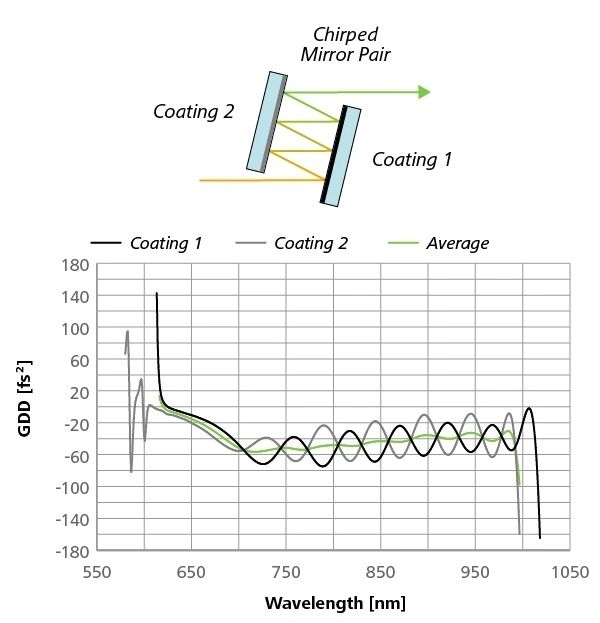

The larger the required bandwidth, the stronger the oscillation of the GDD. In these cases we recommend in principle the mutual compensation of this GDD oscillation with other optical components e.g. by a chirped mirror pair.

Chirped Mirror Pairs

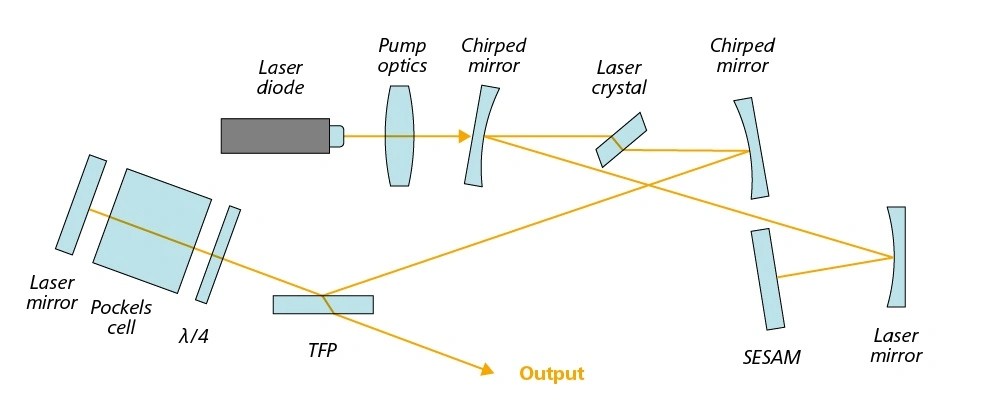

Chirped mirrors are used to compensate dispersion-related travel time differences of ultrashort laser pulses. A chirped mirror pair (consisting of two chirped mirrors) is required if the oscillations in the GDD curve are strong. This is especially the case for mirrors with high bandwidths.

The GDD curve of a chirped mirror does not represent a straight-line curve, but shows oscillations. How strong these are depends, among other things, on the spectral bandwidth. For GDD bandwidths smaller than the bandwidth of a comparable Bragg mirror, the oscillations are rather small. Mirrors with high bandwidth, on the other hand, show strong GDD oscillations.

A correction can be achieved by using corresponding mirror pairs. They consist of two differently coated dielectric mirrors with opposite GDD curves, between which the laser beam can be reflected back and forth as often as desired (see figure). These mirrors are optimized for a small angle of incidence so that a large number of reflections can be achieved.

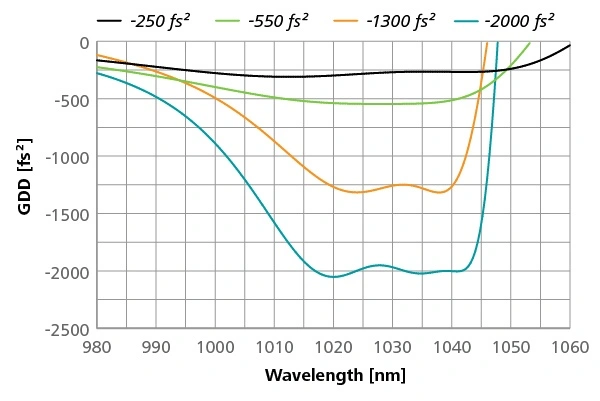

GTI Mirrors

GTI mirrors (Gires-Tournois interferometers) are used for strong time alignment of a very narrow wavelength range. This makes them particularly well suited for compact ps laser systems (e.g. Yb:YAG or Yb:KGW lasers).

| Wavelength Range | Reflectance [%] | GDD [fs²] |

|---|---|---|

| 1020 – 1080 nm | 99.9 | -250 ±50 |

| 780 – 820 nm | 99.8 | -500 ±75 |

| 1040 nm | 99.95 | -1000 ±100 |

| 1030 nm | 99.9 | -10000 ±1500 |

LAYERTEC has been manufacturing GTI mirrors for leading ps laser manufacturers worldwide for over two decades.

For increasing pulse power and/or high repetition rates, you can also achieve the desired correction by using multiple GTI mirrors. For extreme requirements, compromises usually have to be made between maximum reflectivity, GDD value and damage threshold. With heavy loading of such systems, the problem of thermal lensing already occurs before destruction.

Metal Mirrors for Ultrafast Applications

Metal layers of aluminum, silver or gold have the advantage of reflecting light over a wide bandwidth on the one hand and not changing the phase position of the individual waves relative to each other on the other. For this reason, metal mirrors are ideal for the beam guidance of short-pulse lasers.

Additional dielectric coating protects a metal layer against chemical reactions with air components (oxygen, sulfur) with long-term stability. At the same time, the reflectivity can be increased in a limited spectral range, while the phase response remains almost unaffected.

Such reflection-enhanced metal mirrors are also frequently used as scanner optics.

Address

LAYERTEC GmbH

Ernst-Abbe-Weg 1

99441 Mellingen

Germany

International Sales

US Sales Office

Social Media

© 2024 | LAYERTEC GmbH