Special Mirrors

LAYERTEC offers mirrors for a wide variety of specialized application, e.g.

- Metal mirrors with large bandwidth and low dispersion

- Zero Phase Shift Mirrors as well as phase-shifting mirrors

- Resonator mirrors for weak laser lines

- Herriott cells

Metal Mirrors

Metals are well-established mirror materials for low laser power applications. They offer high reflectance over a wide spectral bandwidth (especially in the MIR range) with negligible dispersion-related travel time differences.

LAYERTEC uses the magnetron sputtering process to produce metallic coatings with extremely low stray light losses.

We produce gold, silver and aluminum mirrors. For silver and aluminum mirrors it is advisable to apply an additional protective layer. This prevents them from oxidizing and allows them to be cleaned.

In addition, the reflectance of defined wavelengths can be improved by the targeted application of further layers.

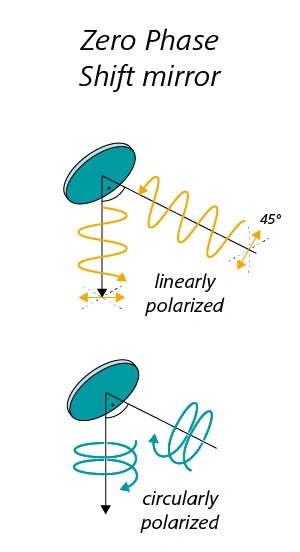

Zero Phase Shift Mirrors

In conventional mirrors, the polarization type of the incident light beam is changed during reflection. For example, s-polarized light becomes p-polarized light. The zero phase shift mirror ensures that the polarization type of the incident beam is maintained. It is used, for example, in laser material processing to guide the laser beam from the source to the cutting head.

LAYERTEC produces zero phase shift mirrors for the wavelength range of 157 – 4500 nm. These components cancel the phase shift between the s- and p-polarized portions of the reflected beam. As a result, the incident polarization mode is preserved.

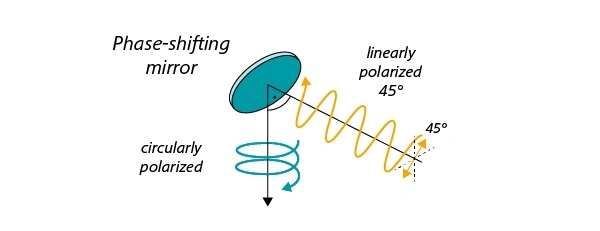

Phase-Shifting Mirrors

Phase-shifting mirrors convert linearly polarized light into circularly polarized light. This effect is particularly useful in laser material processing, where linear polarization would lead to axis-dependent, non-uniform results, e.g. in cuts or drill holes.

Contrary to the way a waveplate works, i.e. transmission of a laser beam under perpendicular incidence, a phase-shifting mirror works by means of reflection and an angle of incidence of 45°. The layer system is optimized to achieve a specific phase difference between s- and p-polarized light.

A typical application is a phase difference of λ/4 ≙ 90° = ℼ/2 at an angle of incidence of 45° to generate circularly polarized radiation for an incident beam with linear polarization. We also realize other values upon customer request.

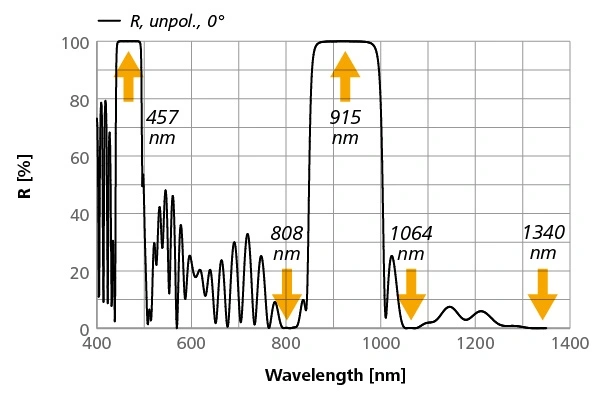

Resonator Mirrors for weak Laser Lines

Neodymium-doped crystals exhibit laser transitions at different wavelengths. However, these are of different strengths. If laser radiation is to be emitted corresponding to the wavelength of a weaker laser transition, the laser lines of the stronger ones must be suppressed.

| Nd:YAG | Nd:YVO4 | ||

|---|---|---|---|

| Laser Line | Second Harmonic | Laser Line | Second Harmonic |

| 946 nm | 473 nm | 915 nm | 457 nm |

| 1064 nm | 532 nm | 1064 nm | 532 nm |

| 1123 nm | 561 nm | 1340 nm | 670 nm |

LAYERTEC offers a variety of laser mirrors where the 1064 nm laser line as the strongest laser transition is suppressed to achieve efficient lasing at other wavelengths. In dependence of the laser setup all coatings are designed and manufactured according customer specifications.

Herriott Cell Mirrors

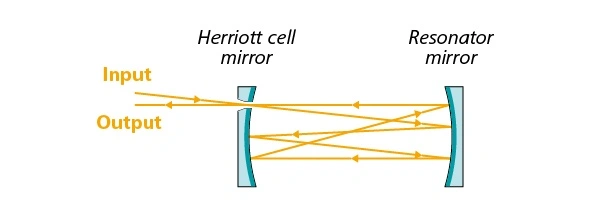

Herriott cells allow the construction of compact resonators by increasing the optical path of a laser beam inside the cavity by multiple reflections. For this purpose, they consist of two spherical mirrors of equal focal length. Heriott cells are used to shorten laser pulses.

One of the two resonator mirrors has a typically acentric bore, which serves as an inlet and outlet opening for, for example, the beam (or a process gas). The inlet and outlet sides each have a conical opening to prevent the beam from being clipped.

In-house precision optics manufacturing enables us to meet complex substrate specifications.

Address

LAYERTEC GmbH

Ernst-Abbe-Weg 1

99441 Mellingen

Germany

International Sales

US Sales Office

Social Media

© 2024 | LAYERTEC GmbH