Technological Evolution

1990 – 2000

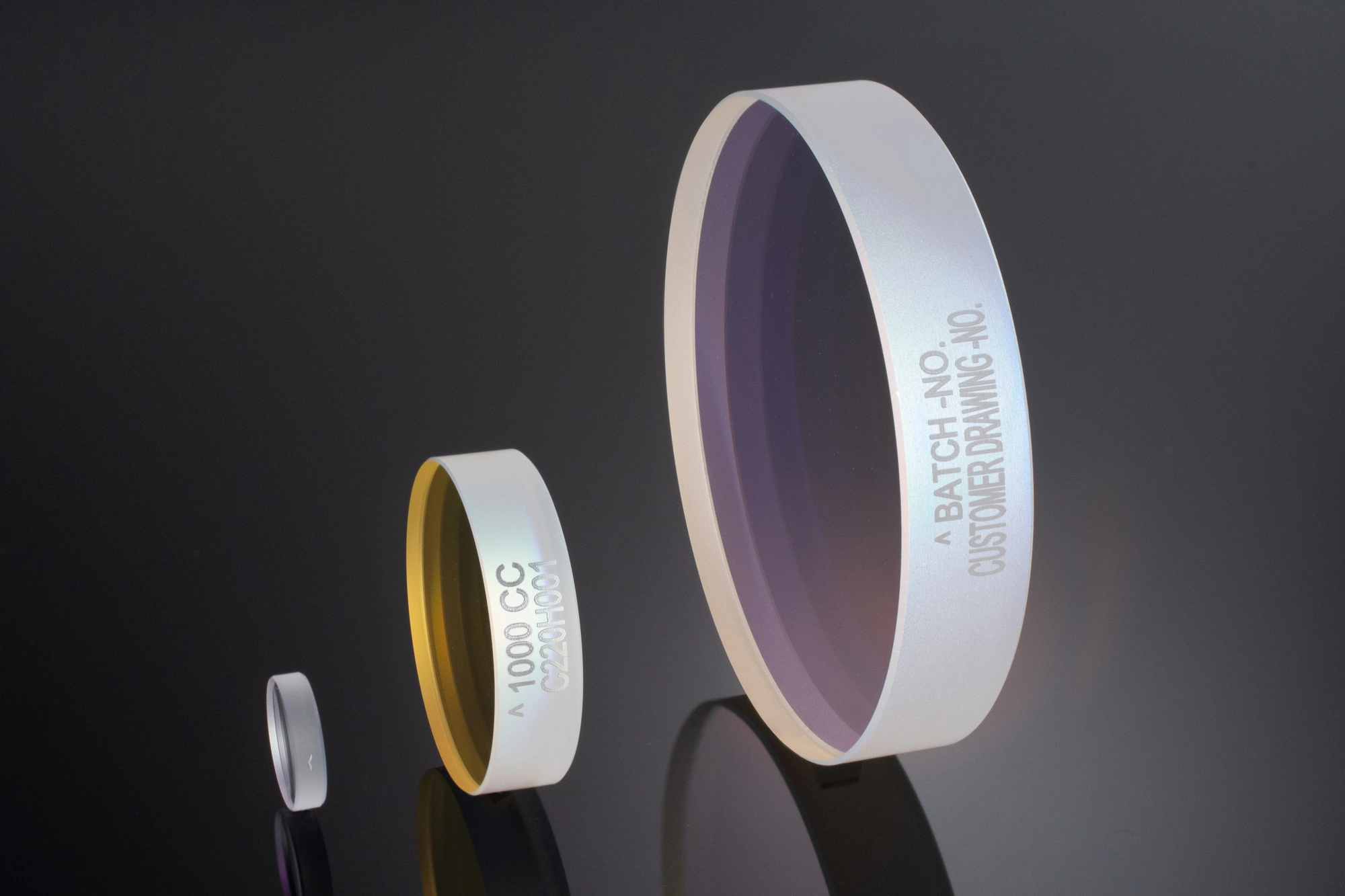

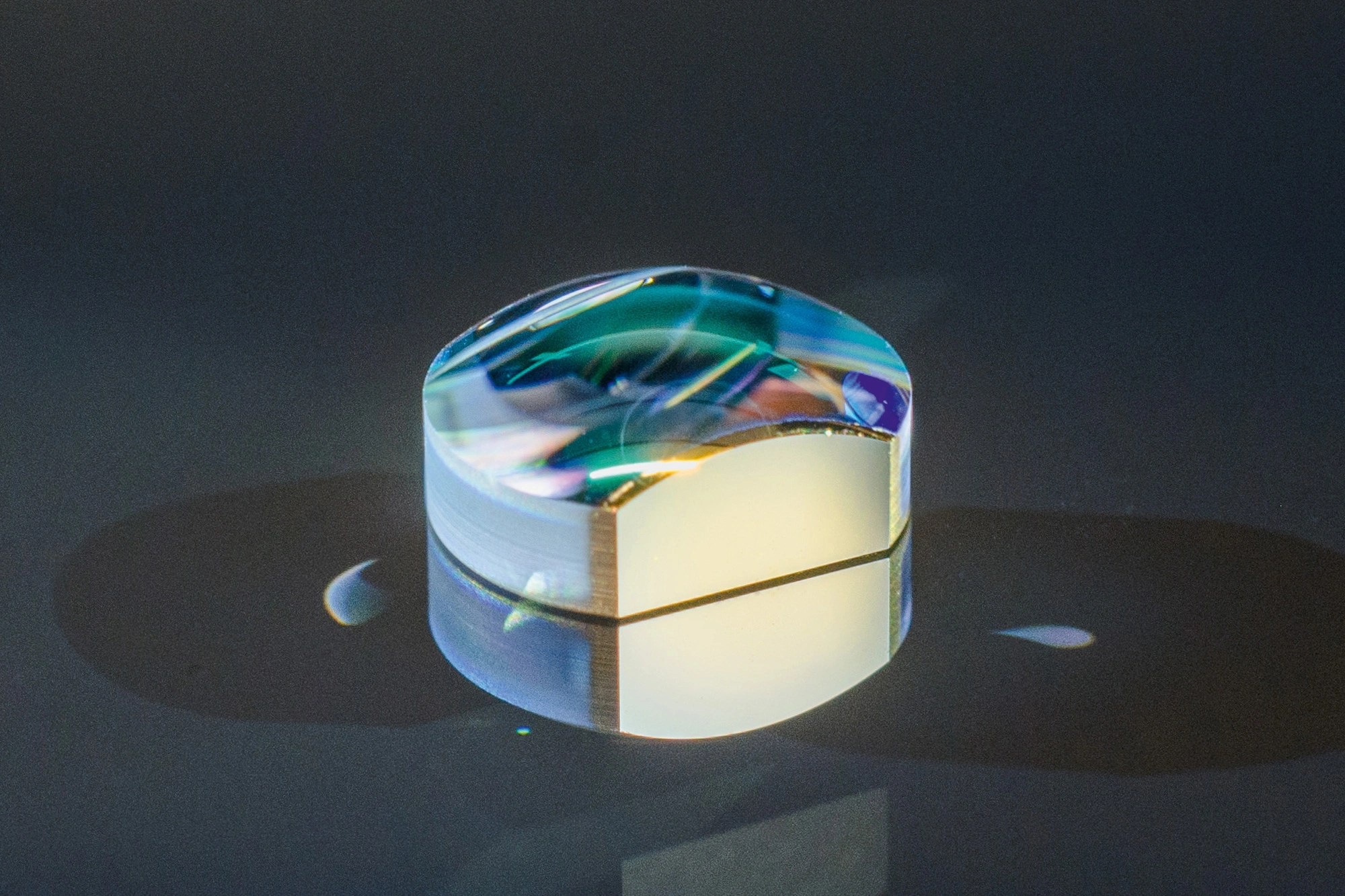

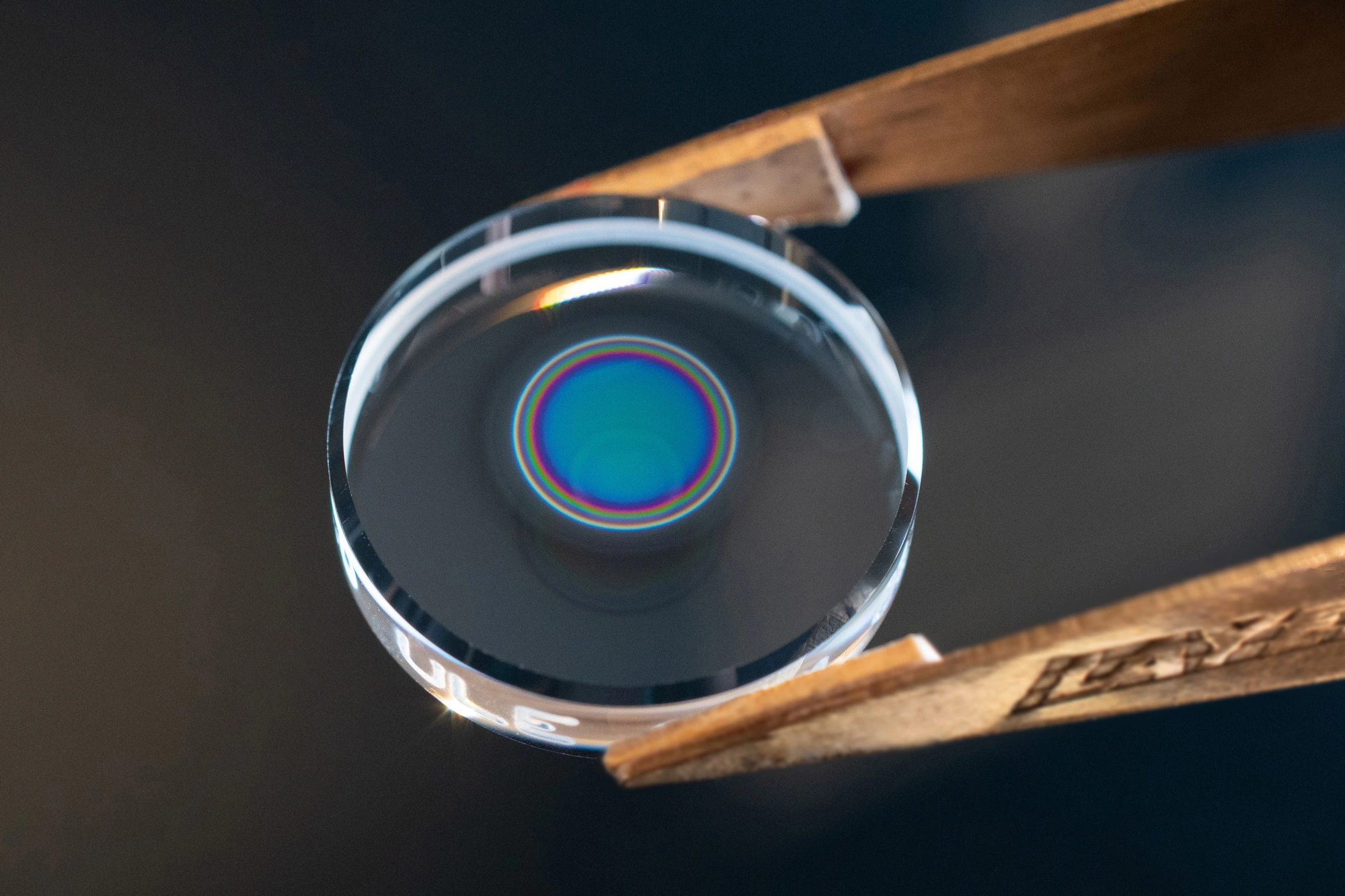

Optical interference coating systems usually consist of a carrier (e.g. a Fused Silica substrate) and a single- or double-sided coating.

In 1992, LAYERTEC started the production of magnetron sputtered coating systems. At the beginning, the substrates were bought externally. In 1993, the company started to build up its own substrate production with experienced precision opticians from the former VEB Carl Zeiss Jena. The complete production chain has been in place since 1994, making it possible to manufacture high performance optics from a single source, starting with the raw glass.

In 1995, evaporated systems made of fluoride and oxide materials for UV applications were sold for the first time.

Further innovations were clean room capable packaging systems and an automated ultrasonic cleaning of coated and uncoated substrates.

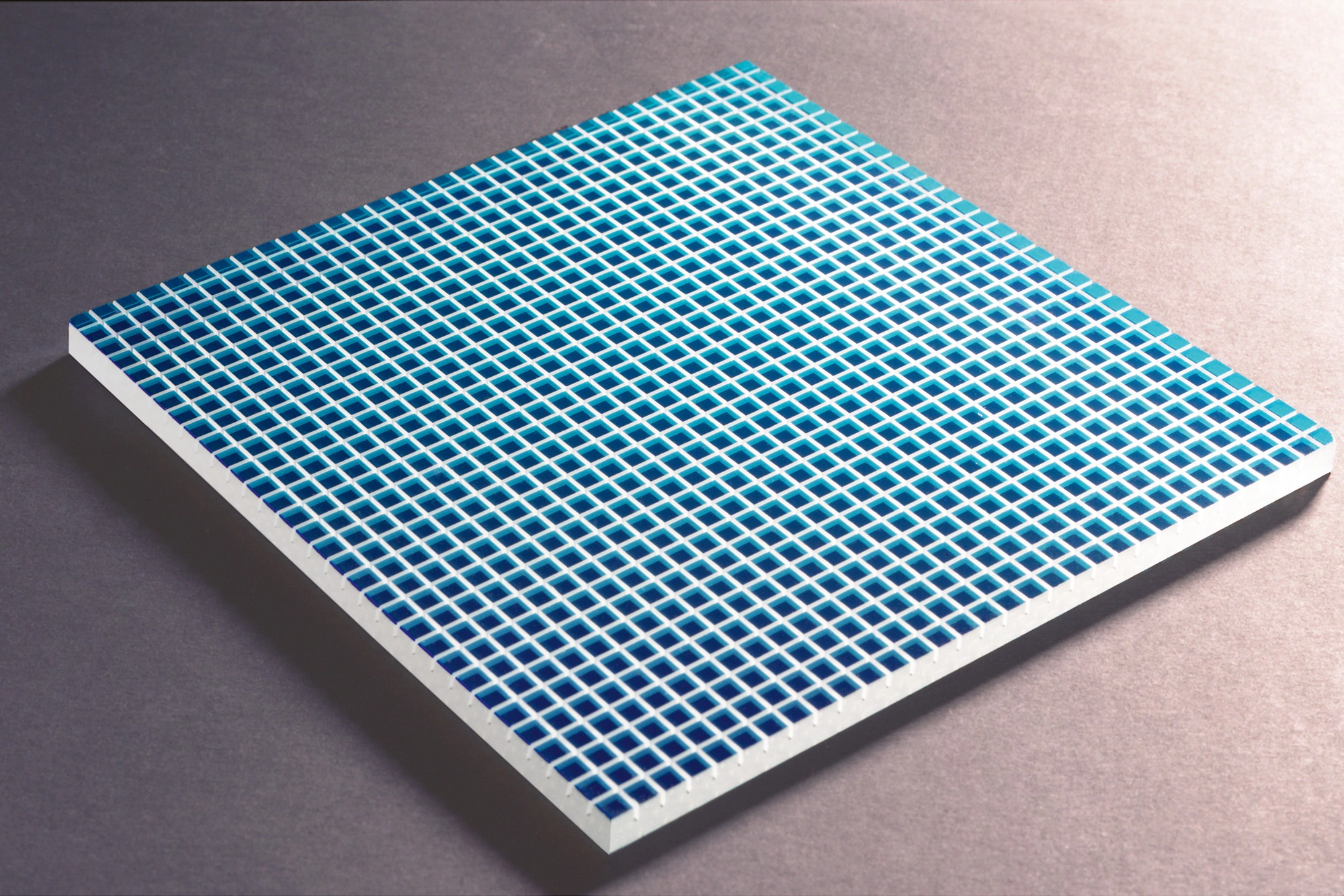

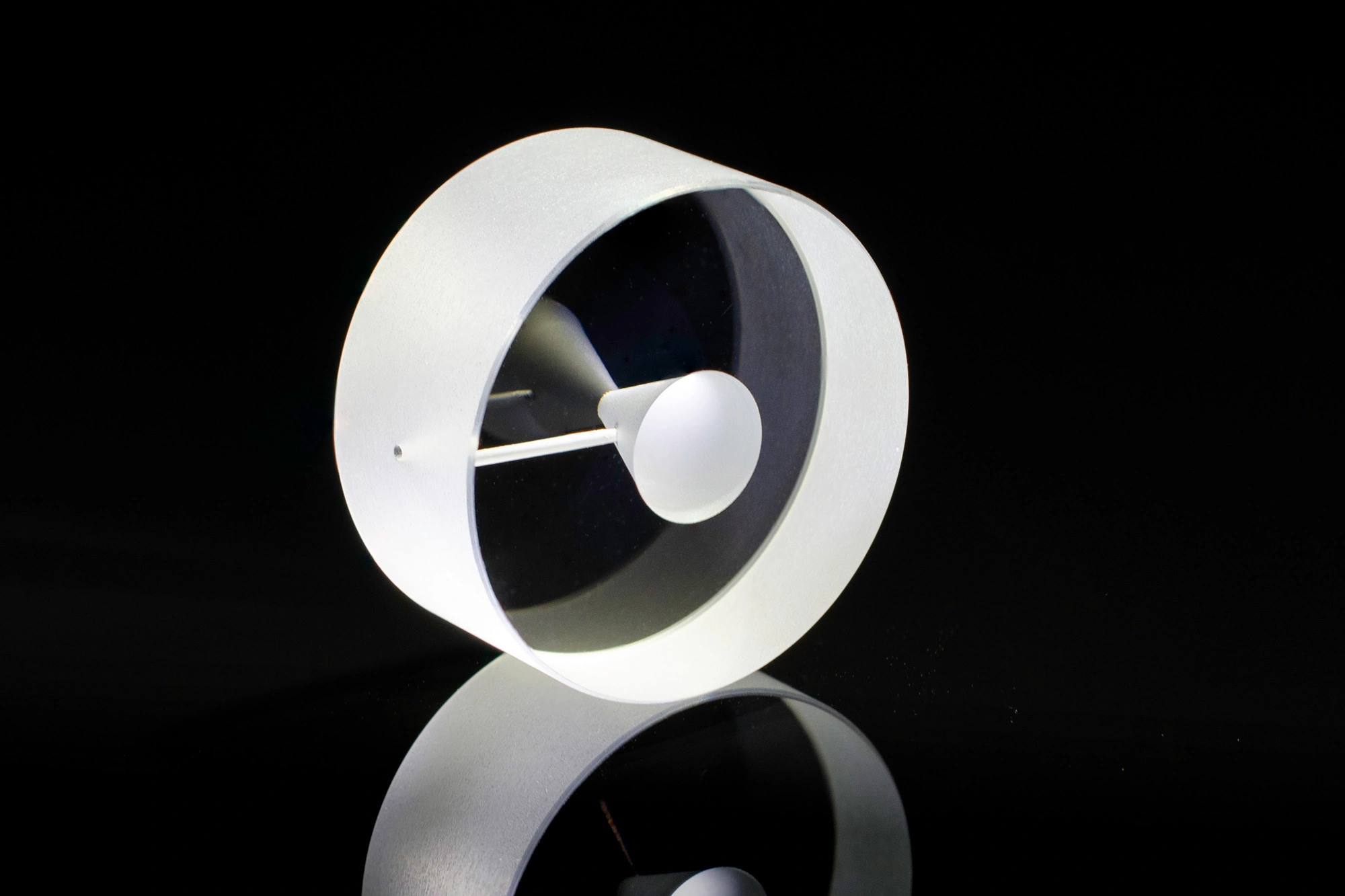

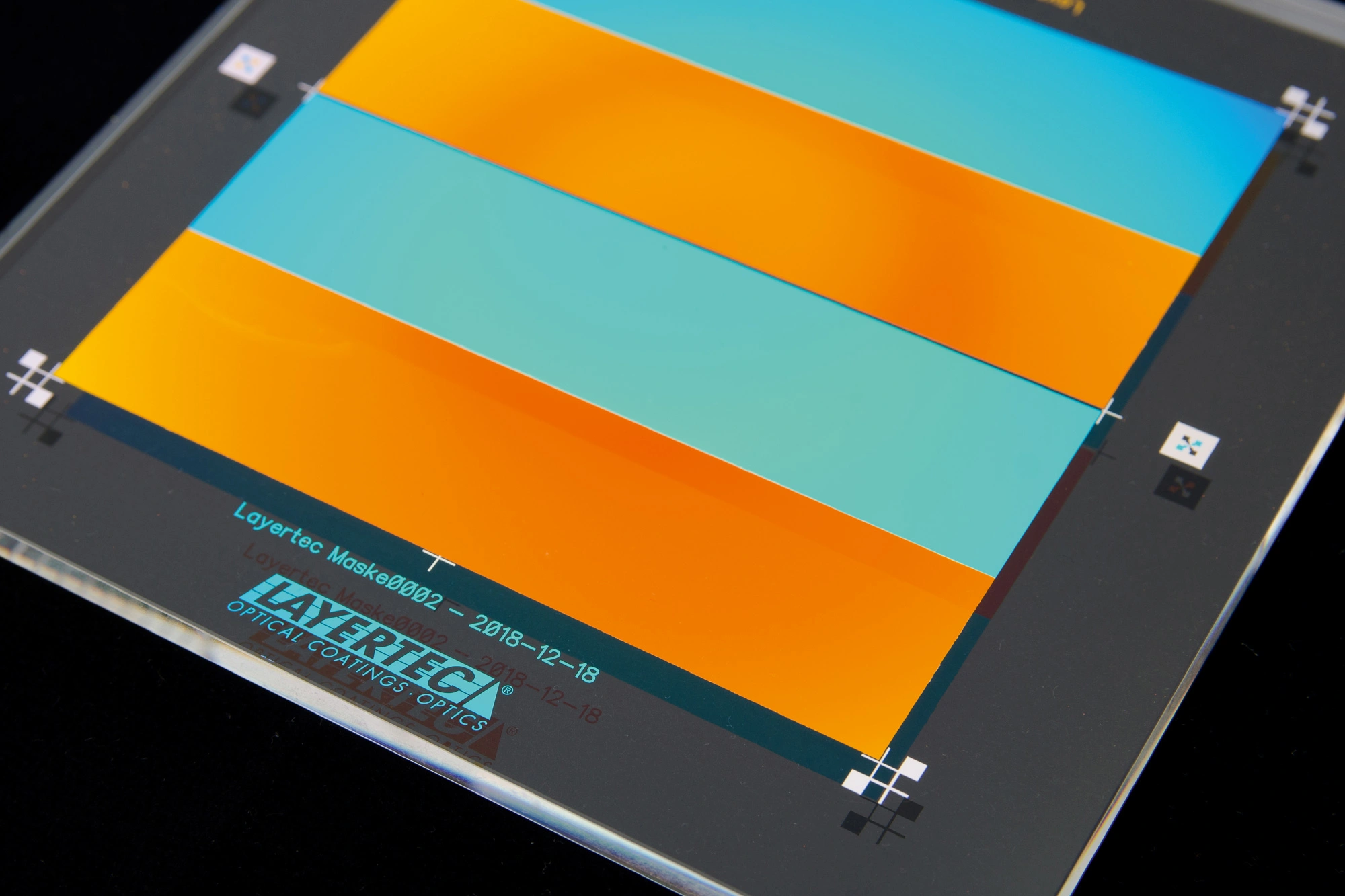

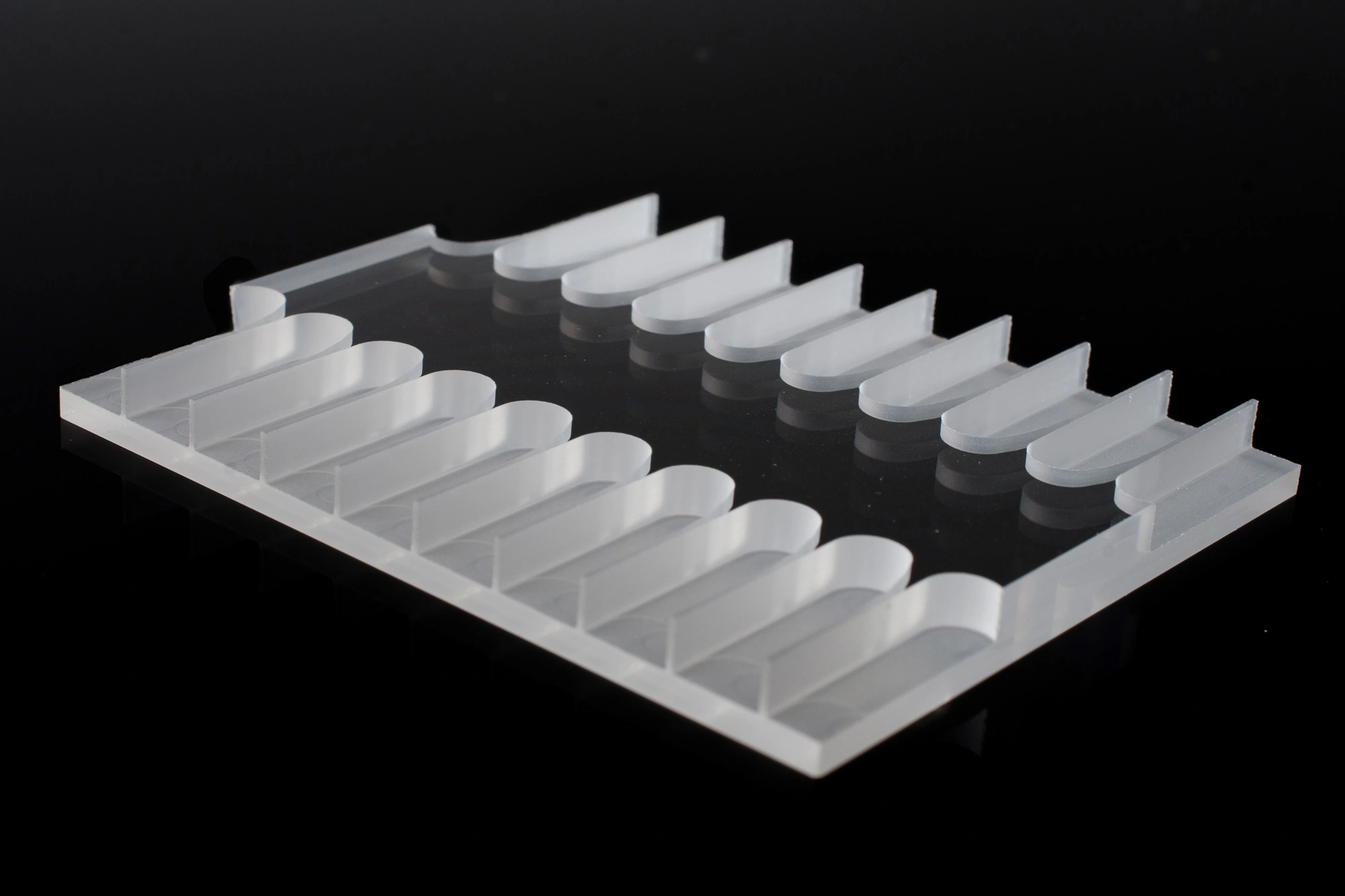

Starting in 1997, it has been possible to customize and supplement the classic production chain (substrate production-cleaning-coating-packaging). Since then, coating is no longer necessarily the last process step in production. For example, low-cost miniaturized, fully coated optics have been added to the portfolio. Here, the smallest parts are diced or drilled out of large coated plates and cleaned fully automatically.

LAYERTEC has always manufactured single pieces for universities and other research institutions. For better marketing an online store was established in 1998.

Coating technologies have been continuously improved since the company was founded. Thus, extremely low-loss interference coating systems could increasingly be produced and components for high power lasers became a core competence.

Dispersive mirrors were produced for customers from Vienna for the first time in 1997/98. LAYERTEC developed corresponding calculation software and commissioned, among others, the Fraunhofer ILT Aachen with the construction of several GDD measurement set-ups.

2000 – 2010

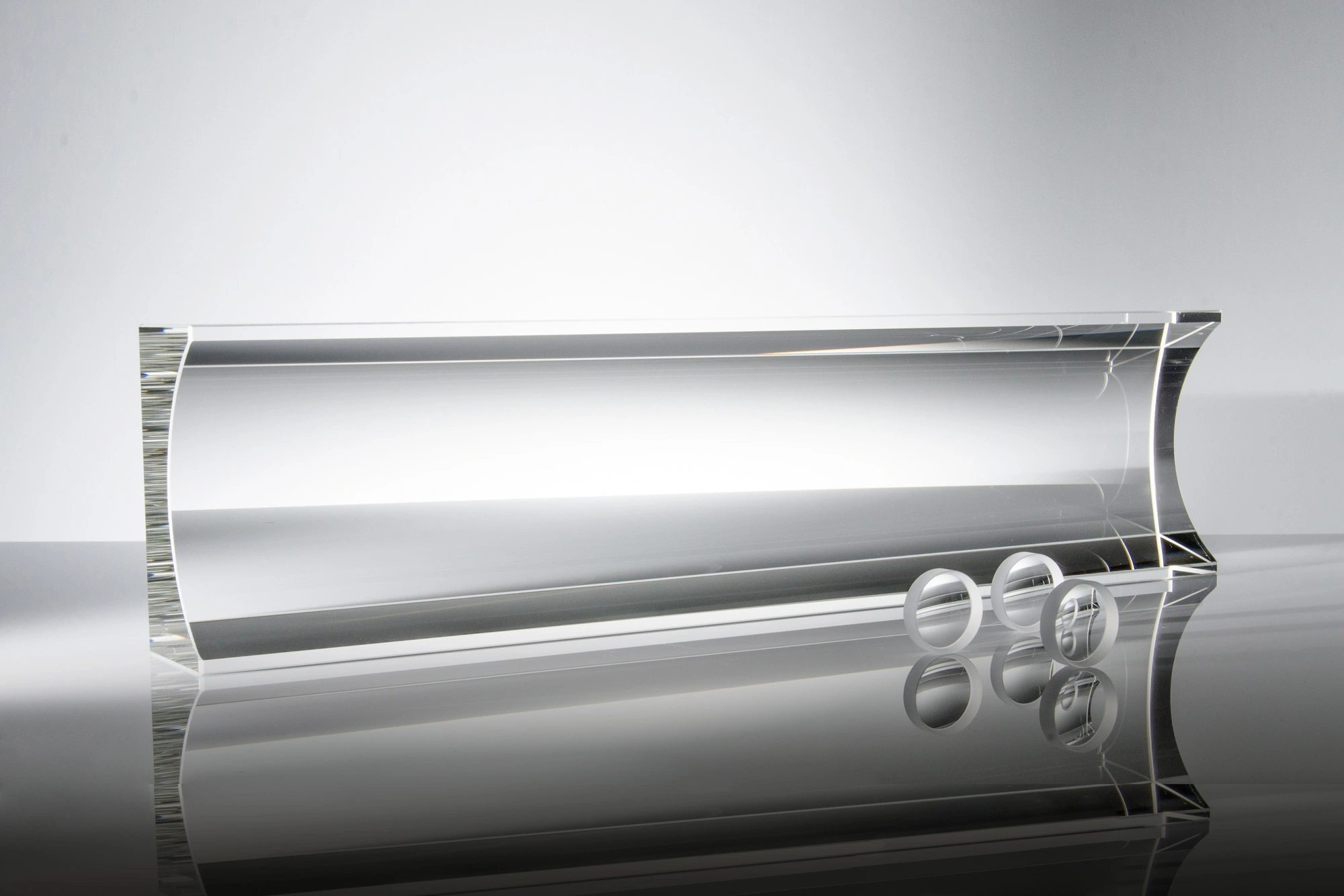

In 2002, the company moved to its current location. Around 2005, there were considerations to produce coated optics up to approx. 600 mm in diameter. An inline sputtering system was set up to coat substrates of this size in 2007.Due to the high flatness requirements of large mirror substrates, it was not possible to use classic planar or spherical grinding and polishing processes. Therefore, zonal polishing was established as a manufacturing technology for the correction of plane surfaces.

This technology enables the production of aspheric surfaces. A special process development and the corresponding metrology were required. LAYERTEC has been able to manufacture and measure aspherical substrates in-house from around 2012.

In 2007, the first IBS coating machines (Veeco) were integrated into the manufacturing process.

2010 – 2023

Between 2010 and 2012, the production space was expanded by several new buildings. Since 2010, LAYERTEC has been investing heavily in technological expertise and the associated development of suitable instruments in the fields of metrology, optics production and ultrasonic cleaning. Based on this expertise, a large number of unique measurement set-ups were created for the characterization of optical properties in the ppm range. Reflectance and transmittance can be measured by several CRD setups. Absorption losses can be determined by PCI. Moreover, an automated defect control system was developed which enables LAYERTEC to characterize polishing and coating defects according to ISO 10110.

In 2013, the entire production control system was converted to SAP in order to efficiently manage the large number of products.

In 2010 and 2012, LAYERTEC installed modern IAD plants which are mainly used for the coating of large optics for high power ultrafast lasers and for line beam optics. Since 2017, LAYERTEC has been meeting the demands of the industry to produce optics with 2.00 m edge length.

For this purpose, the machinery was greatly expanded to include manufacturing, ultrasonic cleaning and the corresponding metrology.

In 2015, LAYERTEC began to laser engrave all finished Fused Silica components.

Around 2018, the technological competence was acquired to change the shape of glass substrates also with ultrasonic technologies or to produce new geometries.

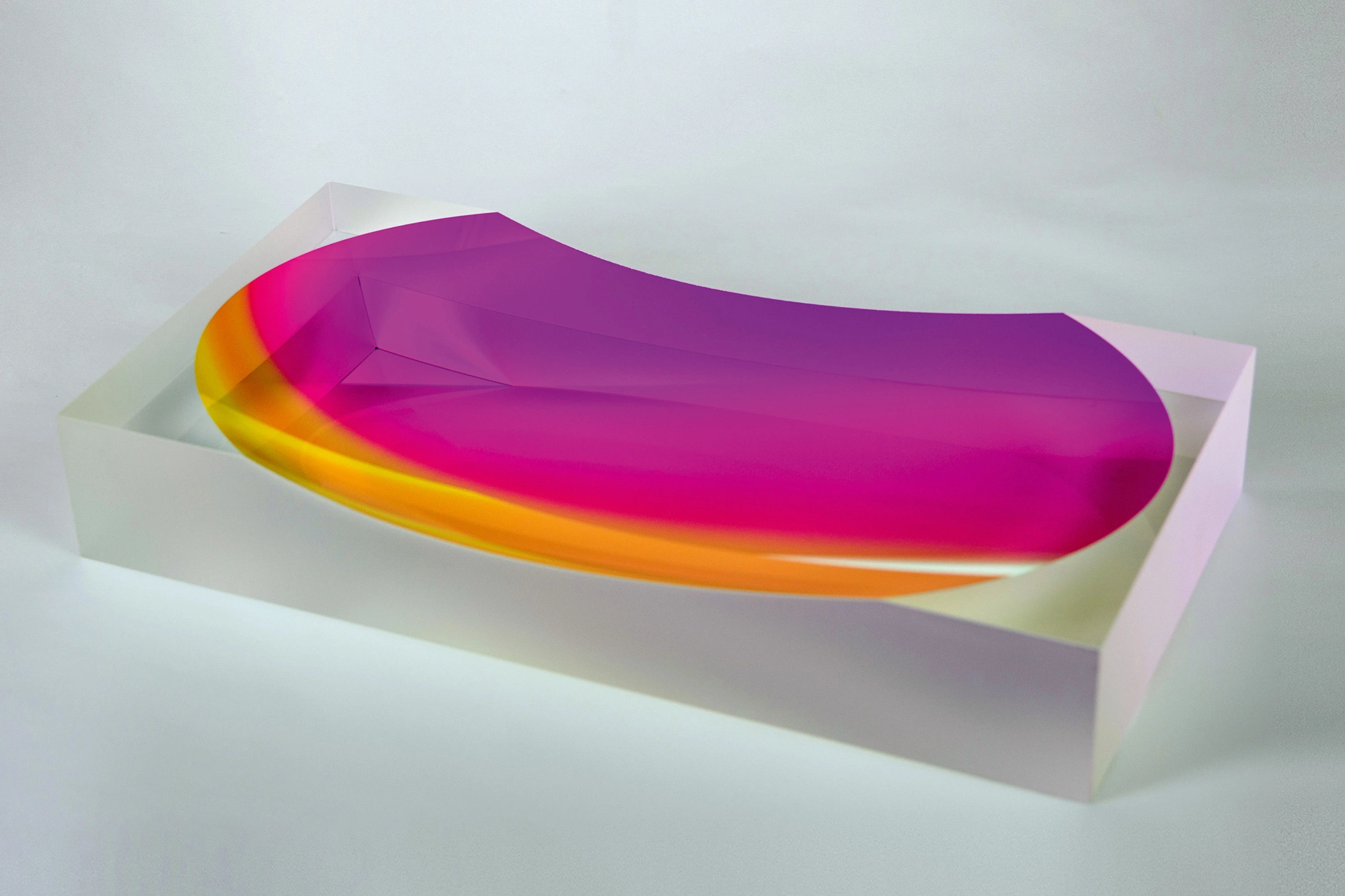

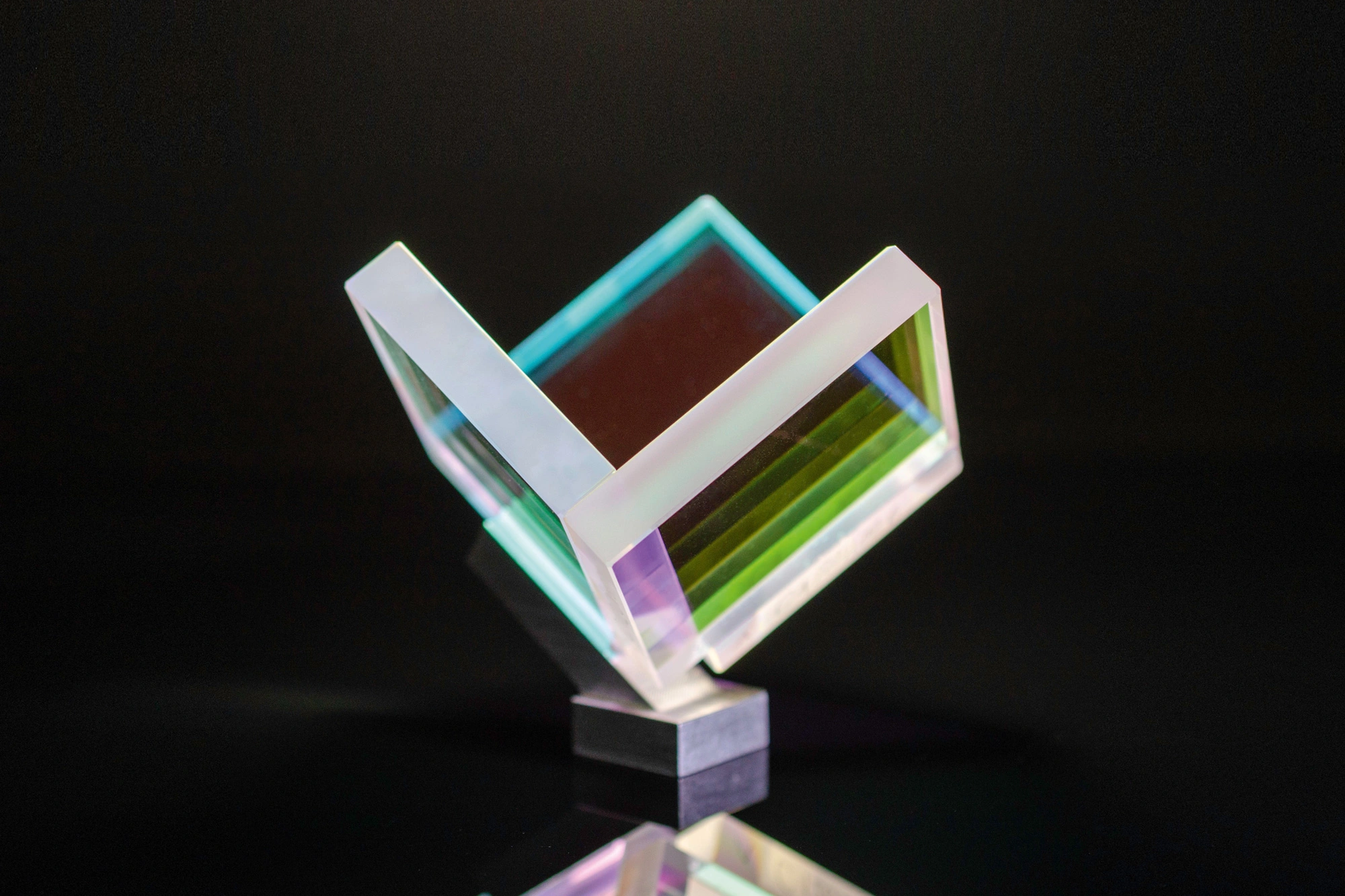

Due to the customer’s wish to use substrates or assemblies with increasing complexity, LAYERTEC started to invest into joining technologies and bonding of surface-activated polished surfaces in 2017. Since then, various joining technologies have been established: optical contacting, adhesive bonding, laser micro welding for unique parts and series production.

New technologies were being tested, including lift-off processes for structuring optical functional surfaces.

Filigree carrier structures are being produced to reduce weight.

LAYERTEC’s solderable coatings support customers in easily joining miniaturized optics.

High finesse cavity mirrors for the NIR and VIS spectral range were developed between 2018 and 2021. LAYERTEC is able to design and produce such mirrors also with two or three spectral regions of high reflectance.

Even during the COVID-19 pandemic, LAYERTEC remained a reliable partner for all customers from industry and research. By concentrating all manufacturing steps in one location, the company was able to overcome bottlenecks in international supply chains.

In 2023, LAYERTEC manufactured over 240,000 coated laser optics, ranging from Ø 1 mm to 2 meters in length, for approximately 700 customers worldwide.

From 2018 to 2022, LAYERTEC planned and built a new facility with more than 6 000 m² of production space to reorganize the entire production.

Address

LAYERTEC GmbH

Ernst-Abbe-Weg 1

99441 Mellingen

Germany

International Sales

US Sales Office

Social Media

© 2024 | LAYERTEC GmbH